Understanding the Importance of Junction Boxes in Weighbridges

Learn about why junction boxes are important in weighbridge systems and why you should use reliable brands.

The only benefit of a “junction- box-less” system is cost

The disadvantages are significant and include:

- Increased risk of water ingression – Each loadcell has two cables going into it, doubling the risk of water ingress due to possible loose and non industrialised connectors.

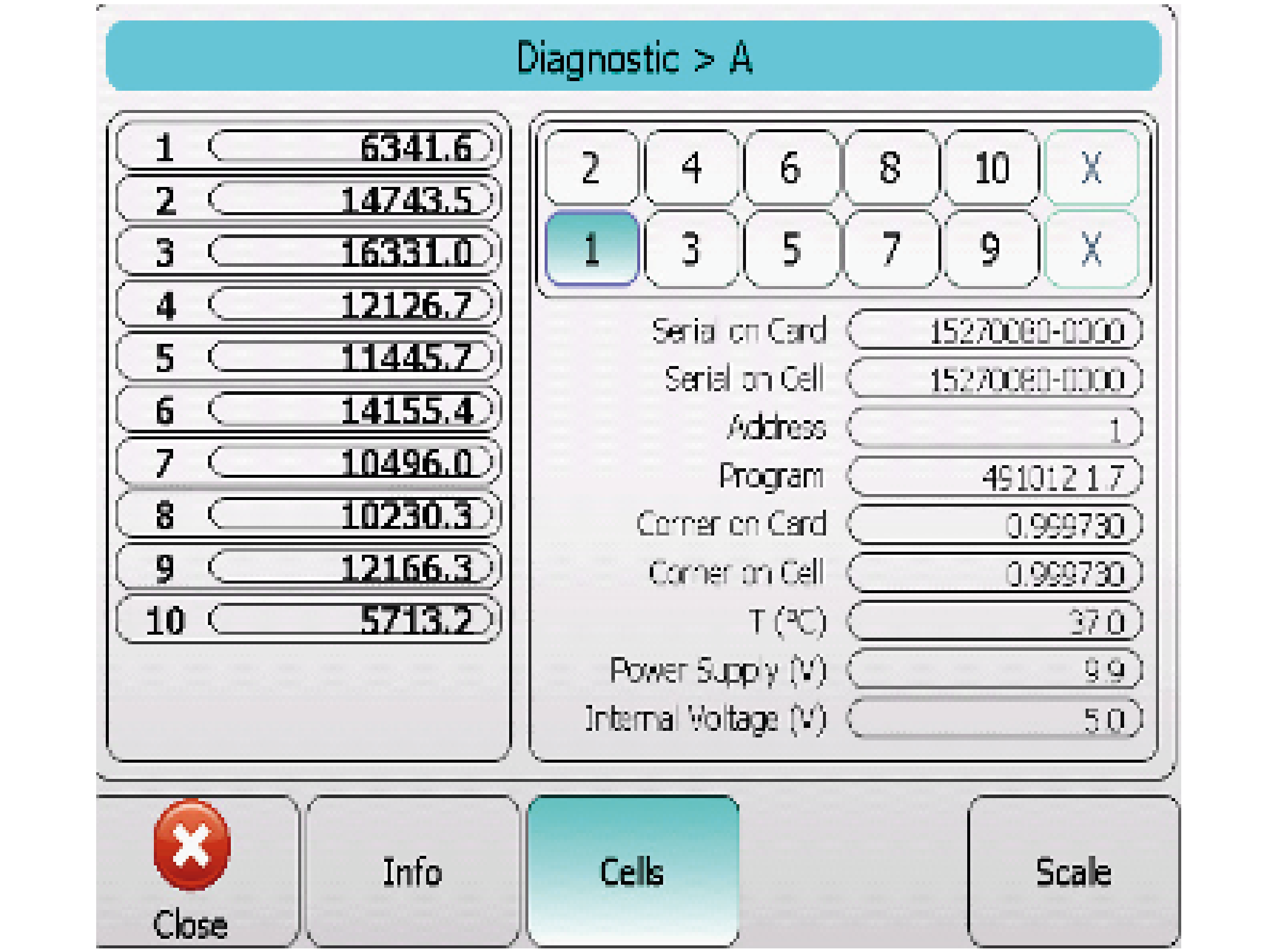

- Inability to reverse calibrate – the indicator sees a string of load cells, and not each load cell, it is not possible for the indicator to store each load cells calibrations, and on a load cell replacement to simple send the correct calibration settings to new load cell. Test weights are therefore need for load cell changes.

- Difficulty fault finding – If the cabling between a load cell is damaged or if a load cell is damaged the entire “string” is broken and it is highly time consuming to work through all the components to find the fault. Unlike for example the DD range of Bilanciai indicators, individual load cell statuses cannot be viewed, and therefore from the status menu it is clear were a fault has arisen.

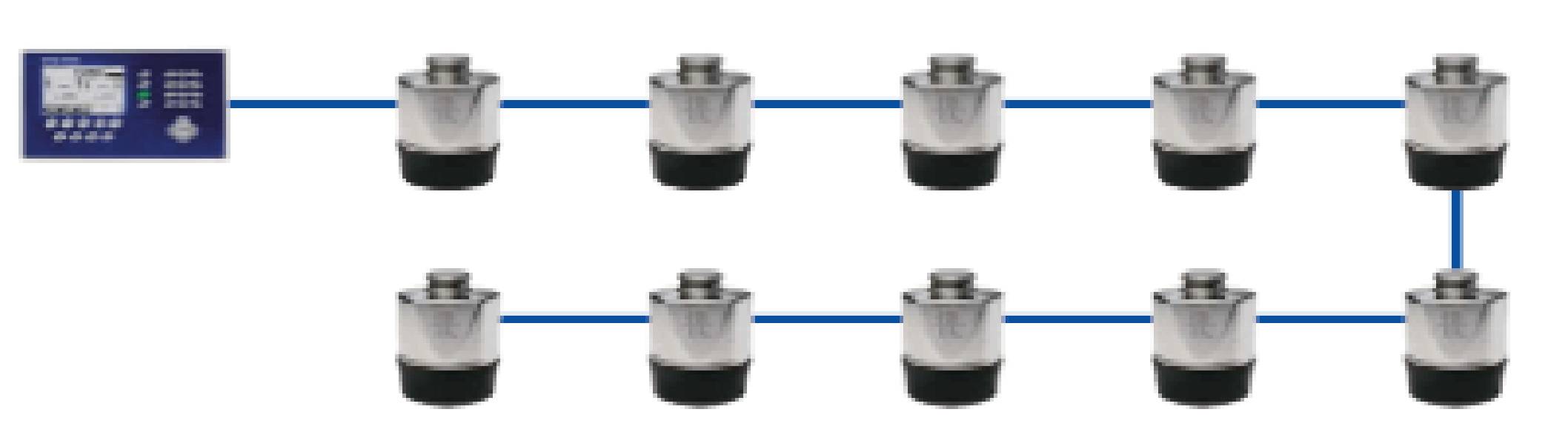

Junction-box “less” system

Thanks for reading!

If you have any questions about our weighing solutions or would like a free quote, please click here to contact us. You can also phone the Sasco Support Centre directly on either +27 83 680 0722 or +27 11 746 6000.

Jonathan is a Kenyan born British national who acquired Sasco from Avery Berkel in 2002 and took on the challenge of revitalizing the then ailing company. Jonathan has been CEO of various listed companies, spent 10 years as an investment banker in London, is committed to innovation and in a firm believer in the exceptional growth prospects for Africa over the coming decades.